Continual Improvement

Pressure Equipment

- Periodic In-service Inspections & Certification

- Design Verification & Registration

- AS4343 Hazard Level Assessments

- Fabrication & Repair Inspections

- Pressure Relief Device (overhaul & re-certification)

- Operational Steam Test Certification

Types: Steam Boilers, Pressure Vessels, Pressure Piping, Pressure Relief Devices.

Asset Reliability

Condition Monitoring & Predictive Maintenance

Route based data collection.

- Route based Vibration data collection & analysis

- Electric Motor Flux testing for rotor bar and stator condition

- Thermography – Electrical and Mechanical

- Acoustic Ultrasonic Emission Monitoring & Analysis

- Motion Amplification – See movement not visible to the eye

Dynamic Balancing of Rotating Elements

- Industrial Fans, Chippers, Augers

Alignment

- Shaft & Machine Alignment

- Alignment Calculator

Non-Destructive Testing

Contracted Services:

- Ultrasonic Flaw Detection

- Ultrasonic Thickness Testing

- Magnetic Particle Inspection

- Dye Penetrant Inspection

- Eddy Current

- Phased Array

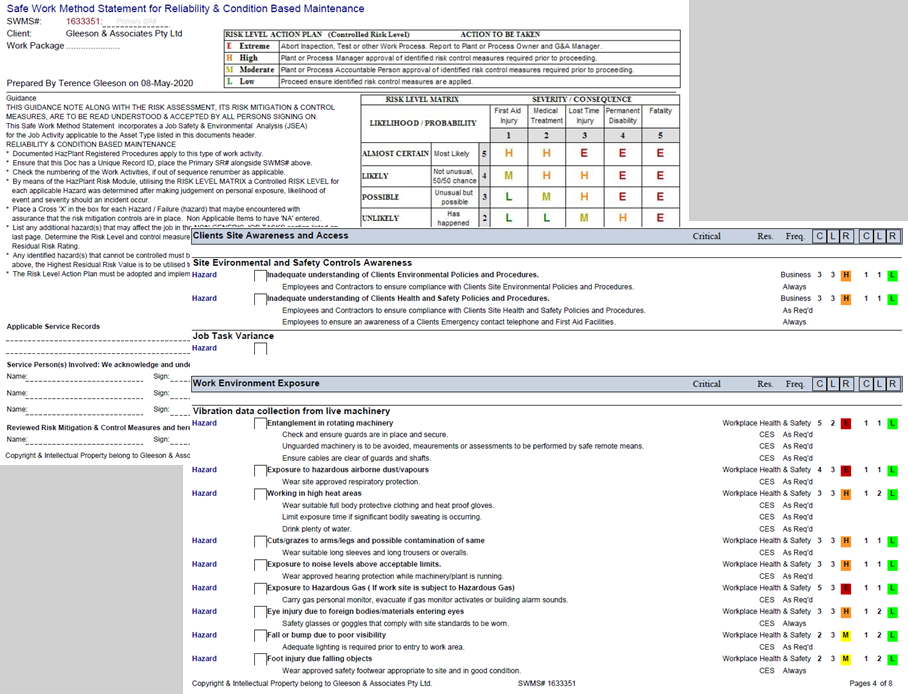

Risk Management Systems

- Risk Based Inspection Analysis

- Operational & Maintenance Strategy

- Job Safety & Environmental Analysis

- Safe Work Method Statement

- Reliability Centered Maintenance

Inspection Body

Scheduled inspections, reporting and certification. Resource team inspection reviews

Prioritised Action items Reporting

Exception Reporting

Onsite and Remote Inspections

Hazardous Plant Records

Inspections and Data

Change of Plant Ownership

Tracking relocation of Plant

Removal of Plant from Service

Plant Register

Registered Designs

Design Verification Records

Design Drawings

Records of Manufacturers Data Reports

Certificates of Conformity Records

Period Asset Imaging